1.SCOPE 范圍 | This specification shall be applied to electret condenser microphone(ECM) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2.MODEL NO. 產品型號 | H9745W005A-56DB | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3.ELECTRICAL CHARACTERISTICS 電氣特性 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Temp. 環境溫度 | 20 ± 2℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Room Humidity 相對濕度 | 65 ± 5﹪ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

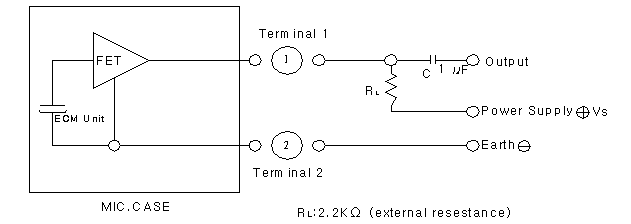

4.MEASUREMENT CIRCUIT 測試電路 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

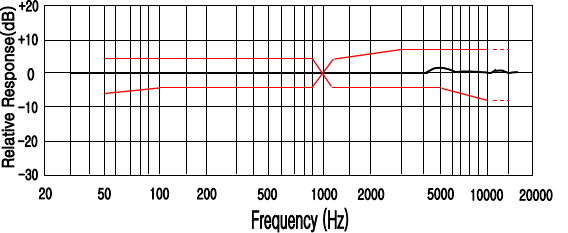

5. TYPICAL FREQUENCY RESPONSE CURVE (FAR FIELD) 頻響曲線 |

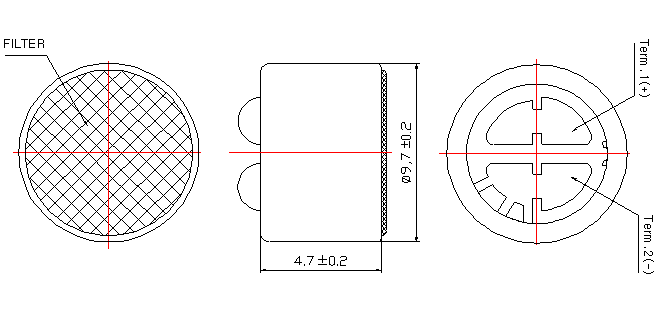

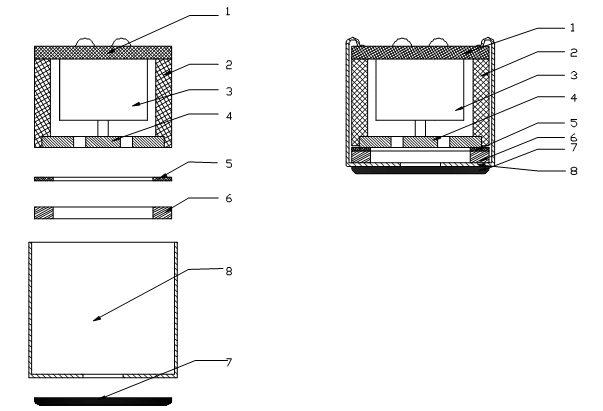

6.DIMENSIONAL DRAWING 外形圖

|

7.RELIABILITY TEST 可靠性測試 | ||

7.1 VIBRATION TEST 振動測試 | To be no interference in operation after vibrations. 10Hz to 50Hz for 1 minrte full amplitude 1.52mm , for 2 hours at three axises | |

7.2 DROP TEST 跌落測試 | To be no interference in operation after dropped to concrete floor each one time from 1meterheight at three directions in state of packing | |

7.3 TEMPERATURE TEST 溫度測試 | -After exposure at 60℃ for 72 hours ,sensitivity to be within ±3dB from initial sensitivity | |

7.4 HUMIDITY TEST 濕度測試 | After exposure at 40℃ and 90 to 95﹪ relative humidity for 72 hours ,sensitivity to be within ±3dB from initial sensitivity | |

7.5 TEMPERATURECYCLE TEST 溫度交變測試 | After exposure at -20℃ for 30 minutes,at 20℃for 10 minutes,at 60℃ for 30minutes, at 20℃ for 10 minrtes.5 cycles ,sensitivity to be within ±3dB from initial sensitivity | |

7.6 TEMPERATURE SHOCK 溫度沖擊 | Temperature change from -20℃ to 60℃ for 30 minures. (changing time :20 sec)After 32 cycles,sensitivity to be within ±3dB from initial sensitivity | |

8 TEMPERATURE CONDITIONS 溫度條件 | ||

8.1 STORAGE TEMPERATURE 貯存溫度: | -25℃ ~ +65℃ | |

8.2 OPERATING TEMPERATURE 操作溫度: | -20℃ ~ +60℃ | |

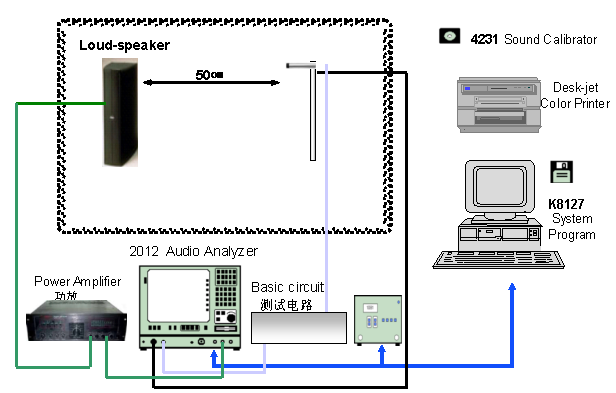

9.MEASUREMENT SYSTEM 測量系統 |

10.REGARDING THE SOLDERING OPERATION 焊接注意事項 |

1 -Recommend to use 15W ~ 30W ceramic soldering iron and apply 330±20℃temperature range |

2 -Soldering should be accomplished within 2 seconds at each terminal so as not to be overheated. |

3 -ECM shall be soldered fixed on the metal block(heat sink)which has the higher radiation effects. Heat sink shall contact with each of ECM. |

4 -The pin hole soldering shall be avoided. |

5 -E.C.M may easily destroyed by the static electricity,and the countermeasure for eliminating the static electricity(the ground for soldering copper,for worktable and for human body)shall be executed. |

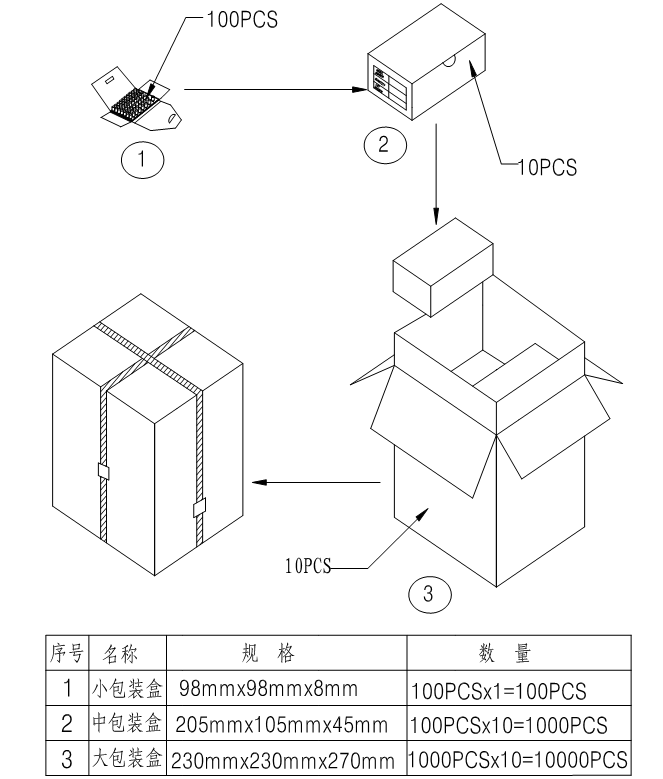

11. PACKAGE 包裝圖

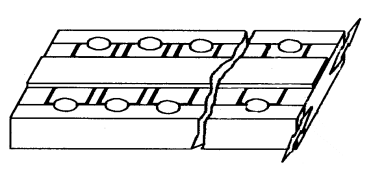

12. List and Structure of Materials 材料及結構清單

No. | Part name | Materials Type | Qty | Origin | Manufacture | Remarks |

1 | P.C.B | Carton | 1 | China | Suzhou |

|

2 | Plastic Ring | ABS | 1 | China | Changshu |

|

3 | FET | 2SK596 | 1 | China | Beijing |

|

4 | Back plate | Copper blank | 1 | China | Changshu |

|

5 | Spacer | Mylar | 1 | China | Hebei |

|

6 | Diaphragm | FEP | 1 | USA | Dupont |

|

7 | FELT | Fabric cloth | 1 | China | Dongguan |

|

8 | Case | AL | 1 | China | Shanghai |

|